“Safety and health at work is a basic principle and right in work” - International Labour Organization.

VisionNav, as a global supplier of autonomous forklifts, strictly controls the product safety design, from hardware to software delivery, not only provides customers with safe and efficient product services, but also creates a safe and fast work environment for blue-collar workers.

VisionNav’s six series of autonomous forklifts, P, R, E, T, L, and SLIM, have passed the extremely strict MD (Machinery Directive) test and RED (The Radio Equipment Directive) test, and obtained the European Union “CE” safety certification. This certification adopts the ISO3691-4 safety standard for driverless industrial vehicles and their systems.

VisionNav’s autonomous forklifts comply with strict selection criteria for electrical components and sensors. The vehicle’s active safety system consists of sensors, encoders, drivers, etc. that have passed the corresponding certification or PL level. The performance level PL of the safety-related parts of the autonomous forklifts, such as obstacle avoidance laser, steering zero position, drive motor encoder, mast high-speed limit safety switch, control system, etc., is higher than or equal to the required performance level (PLr), providing a high level of safety assurance.

Charging safety

VisionNav’s autonomous forklifts are equipped with batteries and chargers that have a temperature control system, a short-circuit prevention system, and an overvoltage and overcurrent electrical control system in their safety design. These systems prevent battery fires caused by high temperature, short circuit, overvoltage and overcurrent.

The battery transportation also obtained the Un38.3 certification and MSDS chemical safety technical specification issued by the United Nations for the transportation of dangerous goods. Through highly simulated, high and low temperature cycles, impact tests, overcharge tests, forced discharge tests, etc., the battery transportation safety is ensured.

The multiple automatic chargers of VisionNav products have passed CE, CB, KC, CSA and other certifications. Among them, the CB system is an international system operated by the “International Electrotechnical Commission Electrical Product Qualification Testing and Certification Organization” (IECEE). A total of 51 countries have 66 certification bodies and more than 270 CB laboratories under them participating in this mutual recognition system. The certification bodies of various countries test the safety performance of electrical products based on IEC standards, and their test results, namely CB test reports and CB test certificates, are mutually recognized by IECEE member countries; KC (Korea Certification) certification is a safety certification system for electronic and electrical products in South Korea. It is a mandatory safety certification system implemented by the Korean Technical Standards Institute (KATS) in accordance with the “Electrical Product Safety Management Law”; CSA is the abbreviation of Canadian Standards Association, and it is one of the most well-known product safety recognition marks in the world.

Obstacle avoidance safety

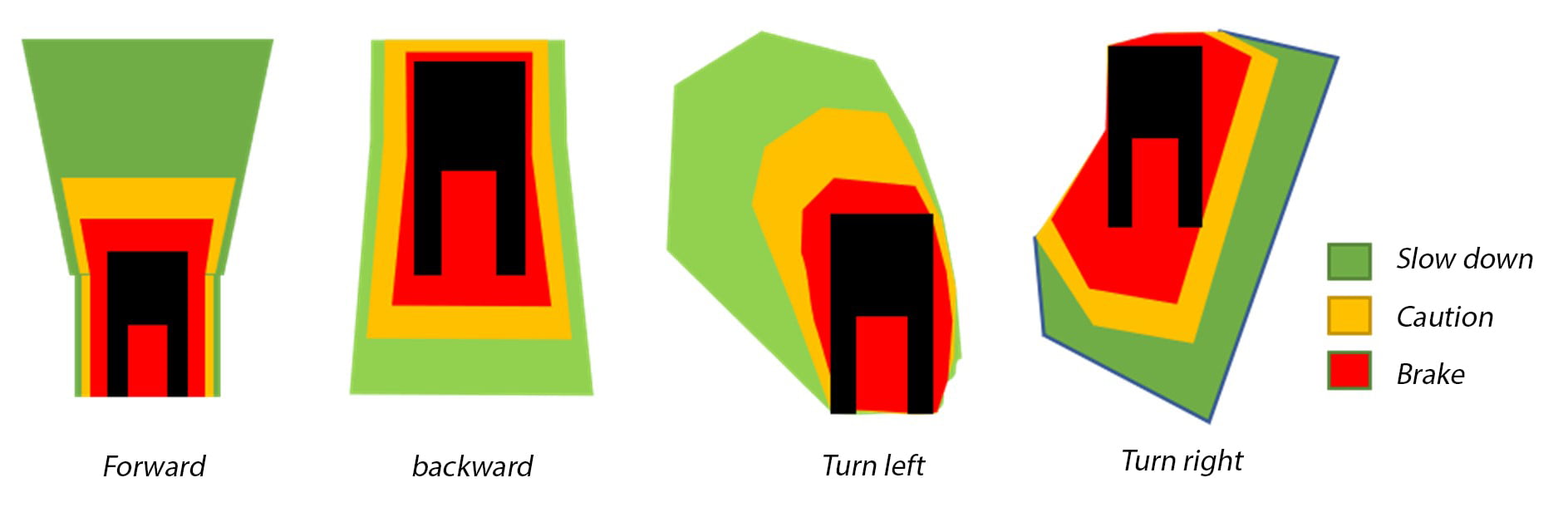

VisionNav designed a special safety PLC control processing unit for the ISO 3691-4 standard to monitor the vehicle’s operating status. The safety PLC control processing unit will cross-check the speed limit level, vehicle speed, and safety laser channel. If an abnormality is found, the safety PLC control processing unit will control the vehicle to decelerate or stop, ensuring the safety of the vehicle and personnel.

The safety laser has a 360° safety coverage range, and can dynamically adjust the size and shape of the laser channel according to the site environment, enabling the autonomous forklift to intelligently adjust its driving speed and vehicle status.

Information security

VisionNav’s information security solution provides customers with a rigorous information security protection plan from three aspects: user security, communication security, and interaction security.

Communication security: All communication behaviors are carried out within the customer’s company intranet or local area network;

Interaction security: When VisionNav RCS2.0 system interacts with the customer’s software system, it customizes token verification to ensure interaction security and prevent the intranet from being invaded by external systems.

With the wide application of industrial mobile robots in manufacturing scenarios, safety has also become one of the key indicators for reliable operation of projects. The product structure and functional design of industrial mobile robots must ensure that they do not cause real or potential harm to people and the surrounding environment when working normally. VisionNav always takes safety as the first line of defense, strictly adheres to the safety line, and creates a safe, efficient and convenient work environment.

About VisionNav Robotics

VisionNav® Robotics is a global supplier of autonomous industrial vehicles and intralogistics automation solutions. Based on Machine Learning, Environmental Perception, Deep Machine Learning, and Servo Control technology, VisionNav has developed nine product series for full-stack scenarios to automate industry logistics. VisionNav has served more than 30 countries and deployed 350+ projects around the globe, and partners with 50+ Fortune 500 companies, covering auto manufacturing, tire, food, petrochemical, e-commerce, 3PL, pharmaceutical, and other industries.

Publish Contact

Iris Chen

xchen@visionnav.com