AGV and AMR Robot-Driven

Logistics Automation Solutions

for Smart Warehousing & Manufacturing

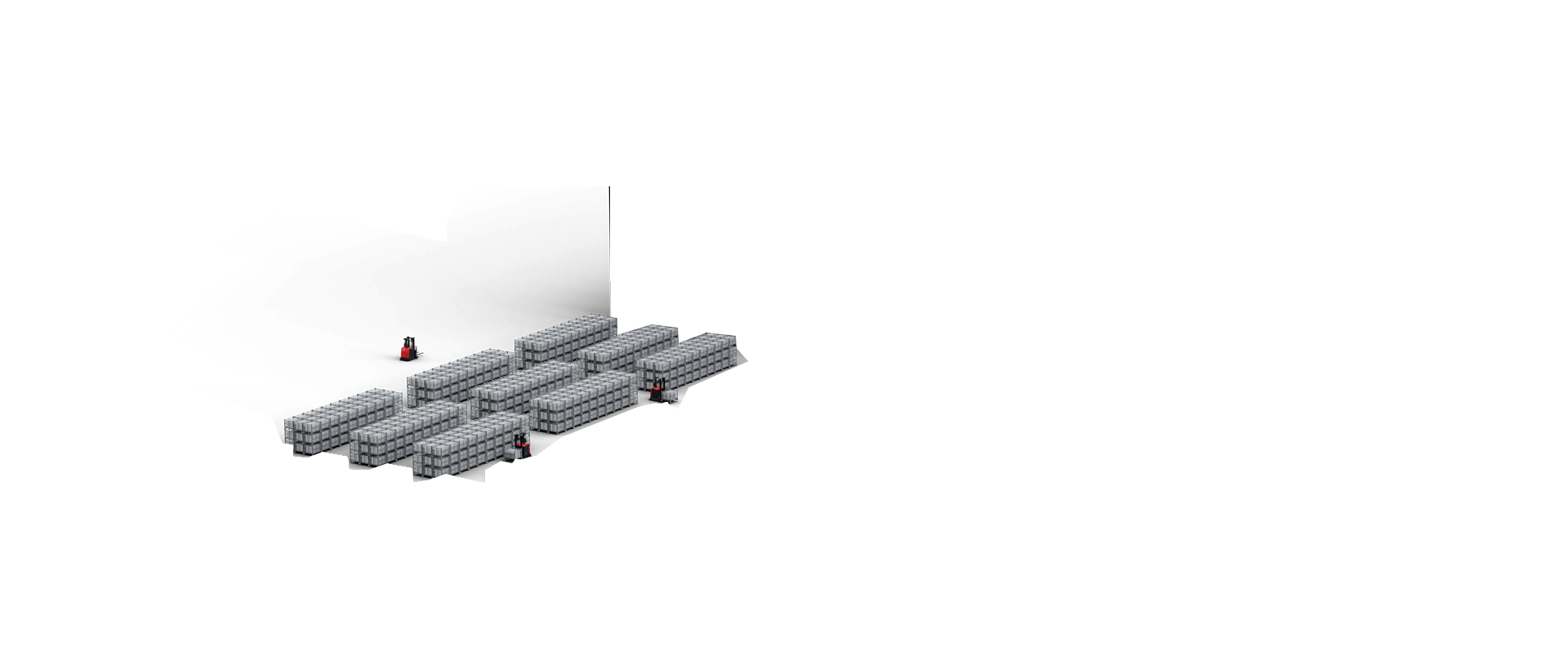

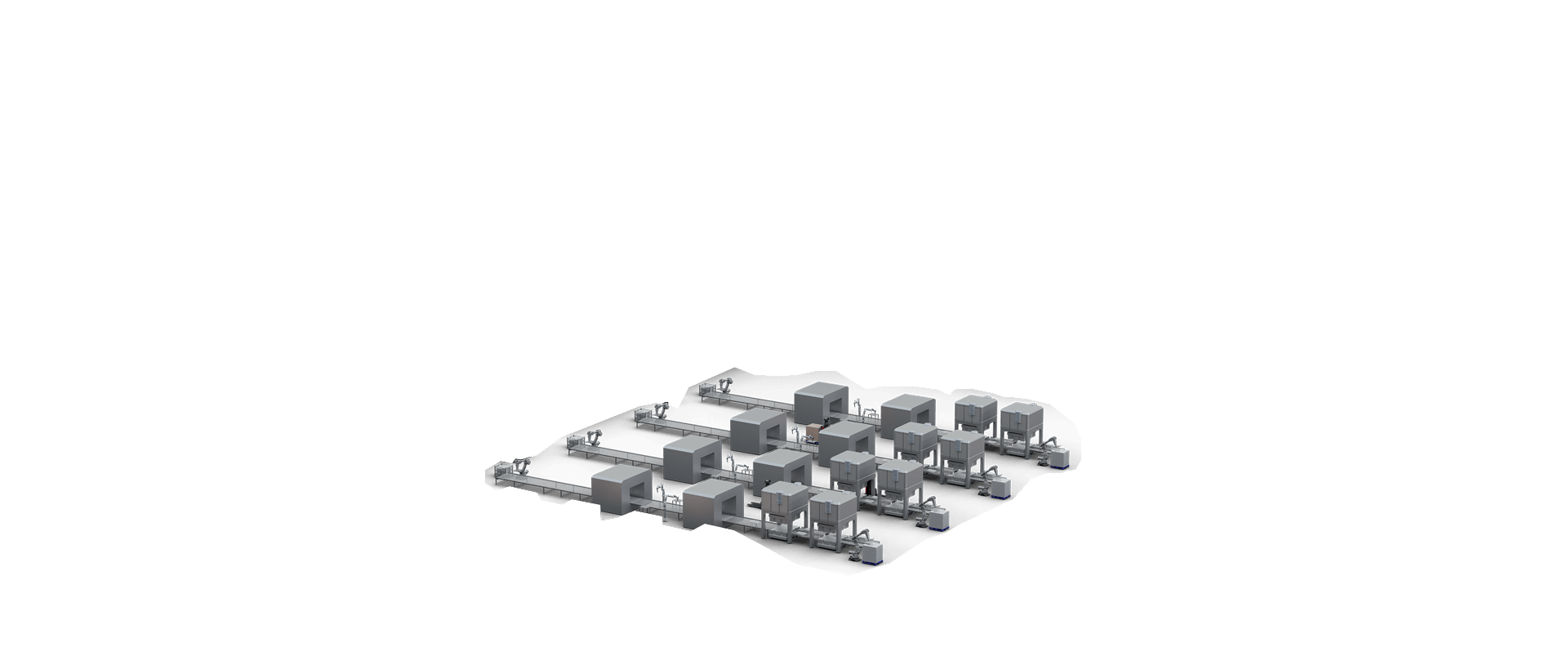

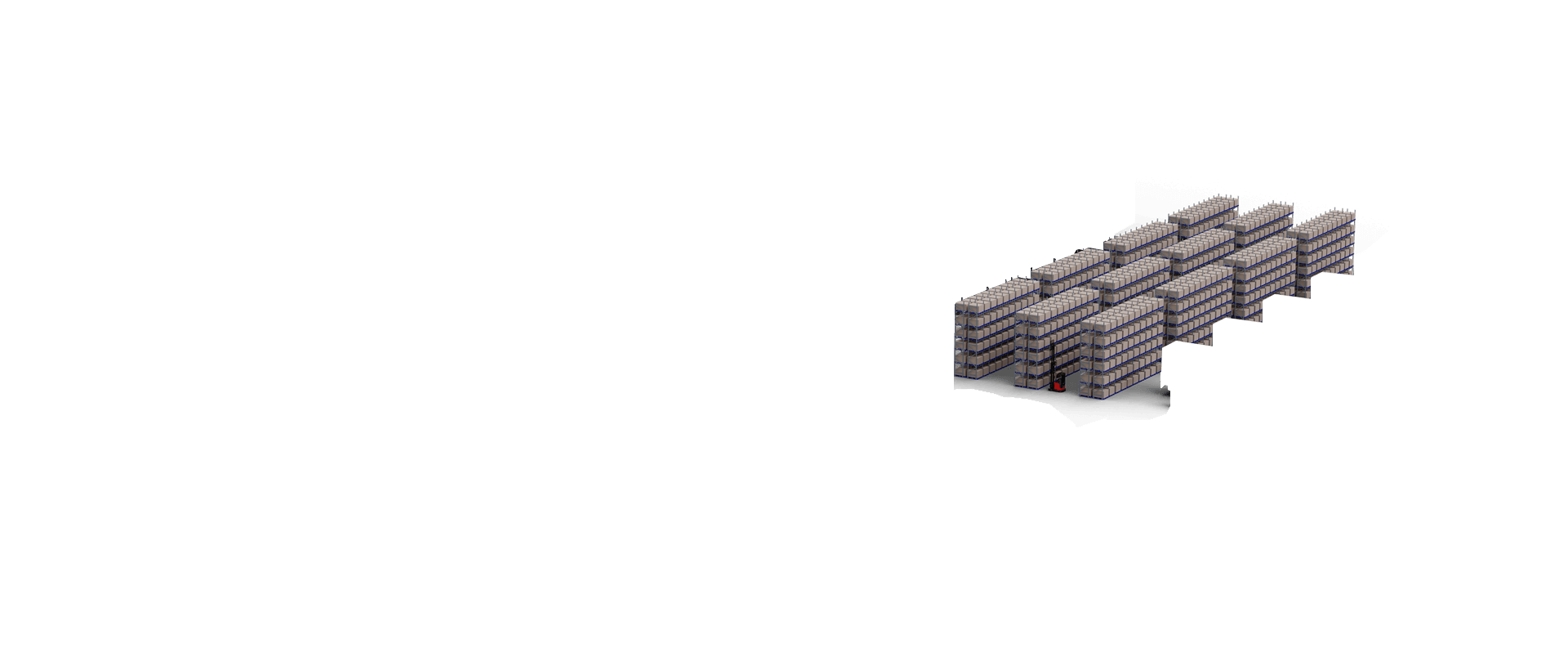

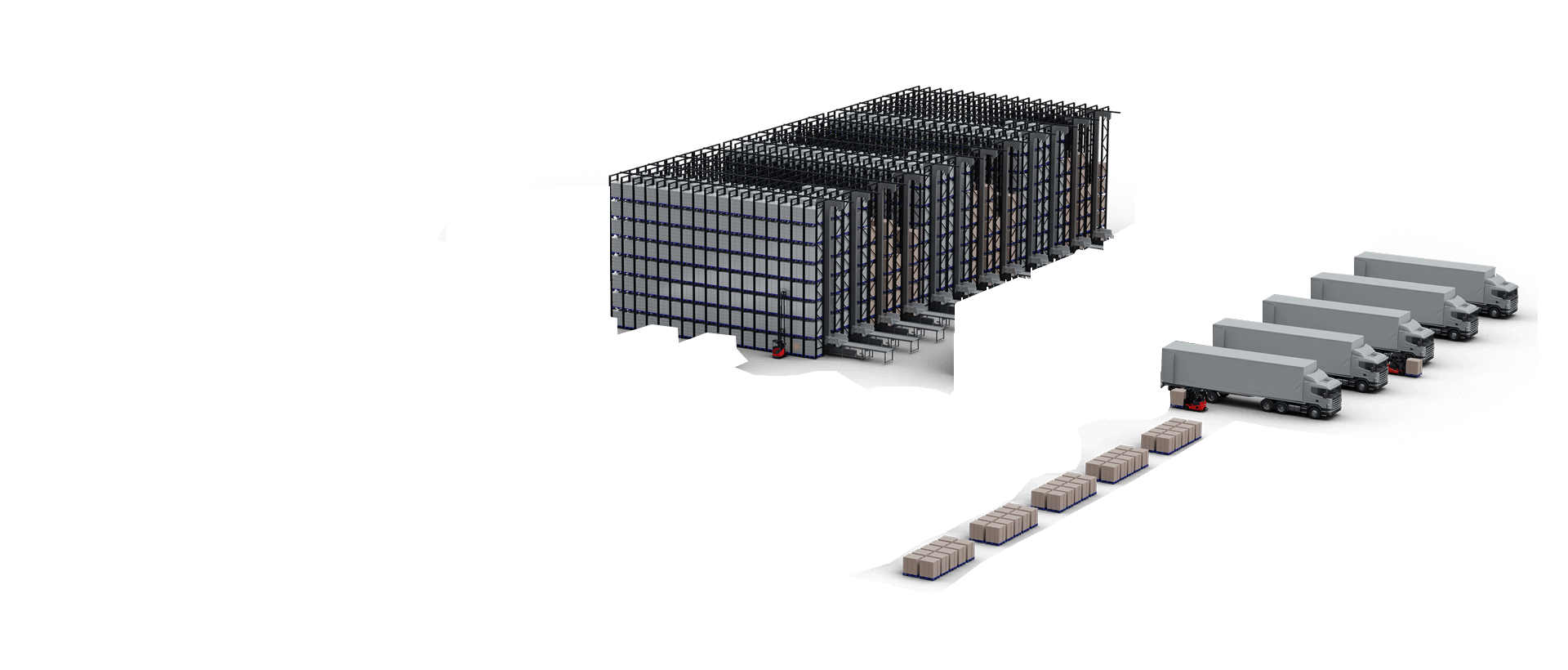

Automated handling of a wide variety of goods in factories and warehousing industries, including

Ground-Ground Transportation, Truck Loading and Unloading, Multi-layer Stacking,

High Bay Putaway, Indoor & Outdoor Traction and More.

Redefining Autonomous Industrial Vehicles Based On Visionnav Driverless Platform Environmental Perception, Deep Learning, Servo Control Technology

Deepen Into Complex Scenarios, Create Better Human-Machine Collaboration, Improve Logistics Efficiency And Space Utilization, And Generate Value For Customers

Headquartered in Atlanta, VisionNav® Robotics is a global leader in autonomous industrial vehicles (AMRs/AGVs) and logistics automation solutions. Utilizing deep learning, environment perception, and servo control technologies, VisionNav has developed nine product series to address full-stack material handling scenarios. With over 750 projects deployed across more than 30 countries, VisionNav is trusted by numerous Fortune 500 companies in industries such as automotive, food and beverage, chemical, pharmaceutical, and 3PL, enhancing operational safety, efficiency, and future readiness.

AGV forklift picks up the goods from the truck and transports them to the designated area