Intralogistics features multiple processes, mixed operations, and low coupling capacity between various intralogistics links. These factors lead to overall logistics inefficiency and looseness. In addition, due to the diversification of market demands, manufacturing enterprises are seeking partial logistics automation solutions and aspiring to break through the bottlenecks of multiple processes and diversification through an all-in-one and more integrated management system.

As a global supplier of autonomous industrial vehicles and intralogistics automation solutions. VisionNav offers a comprehensive range of products, from Automated Guided Forklifts (AGFs) to Autonomous Mobile Robots (AMRs). VisionNav covers intralogistics across all scenarios through various product combinations and flexible model expansions. This helps customers address end-to-end automation processes, ranging from material handling and warehouse entry and exit to rack loading and unloading, using various solutions that cater to different needs.

VisionNav Solution

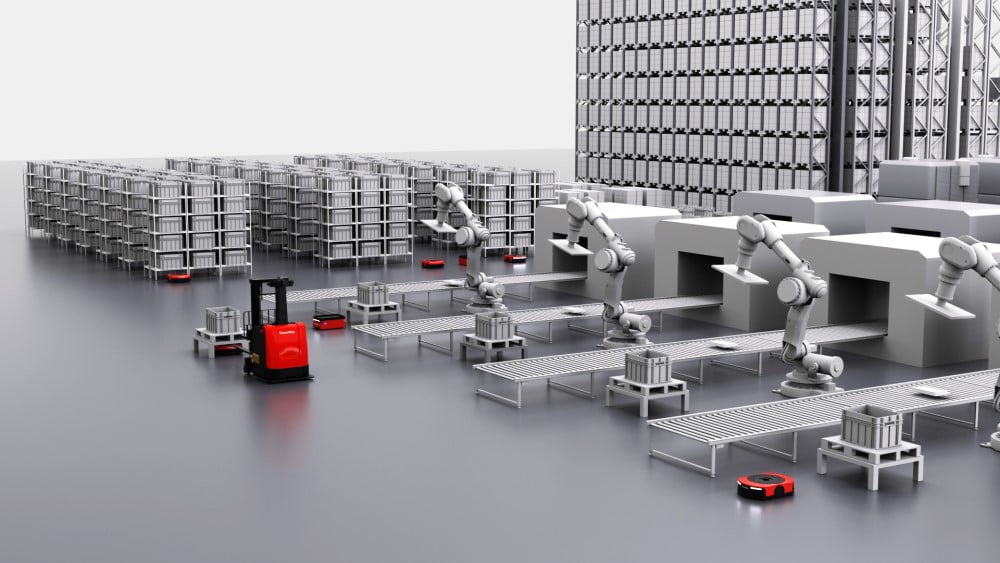

AMR x AGF Fleet

VisionNav's automated handling solution combines autonomous forklifts and AMRs for various intralogistics scenarios. This integration bridges scenarios including material handling, inbound and outbound of the warehouse, and rack loading and unloading, effectively coordinating material handling of different frequencies seamlessly. The entire solution process is managed through VisionNav's integrated system, addressing the challenge of low coupling across multiple stages. The system assists enterprises in achieving a resolution to the challenges of intralogistics automation at one stop.

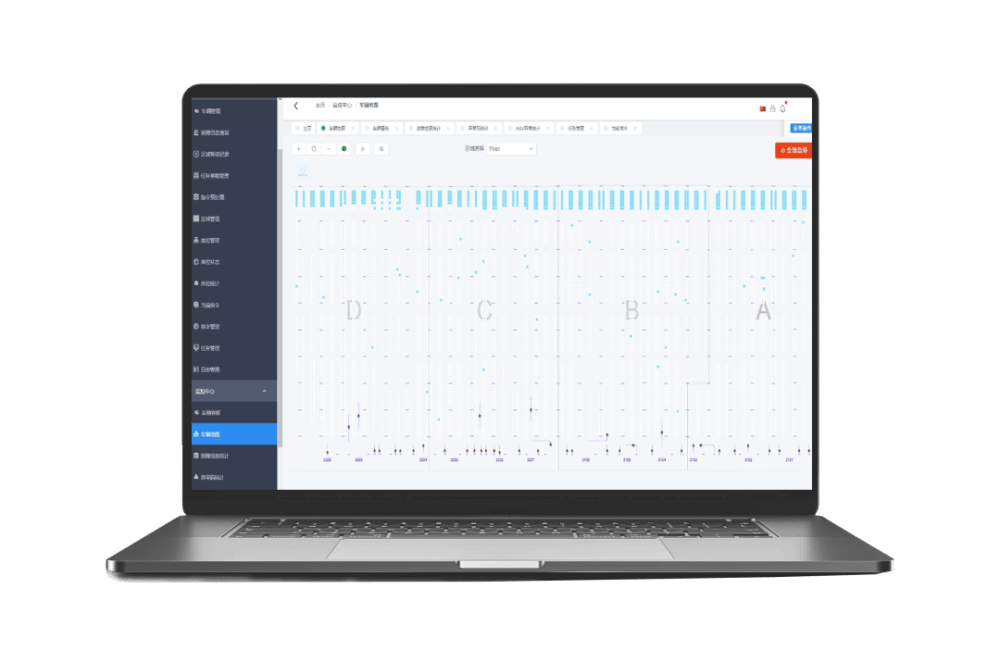

One System for All Scenarios

VisionNav Central Control System(RCS) 2.0 serves as the "brain," providing the end devices with robust and stable algorithms and task-processing logic. It enables automatic task assignment and real-time route optimization, seamlessly integrating with customers' MES, WMS, and other systems to establish a streamlined flow and facilitate lean, collaborative production. This unified system solves the issue of interconnecting and linking various devices within an enterprise.

RCS 2.0

Solution Advantage

Case Study

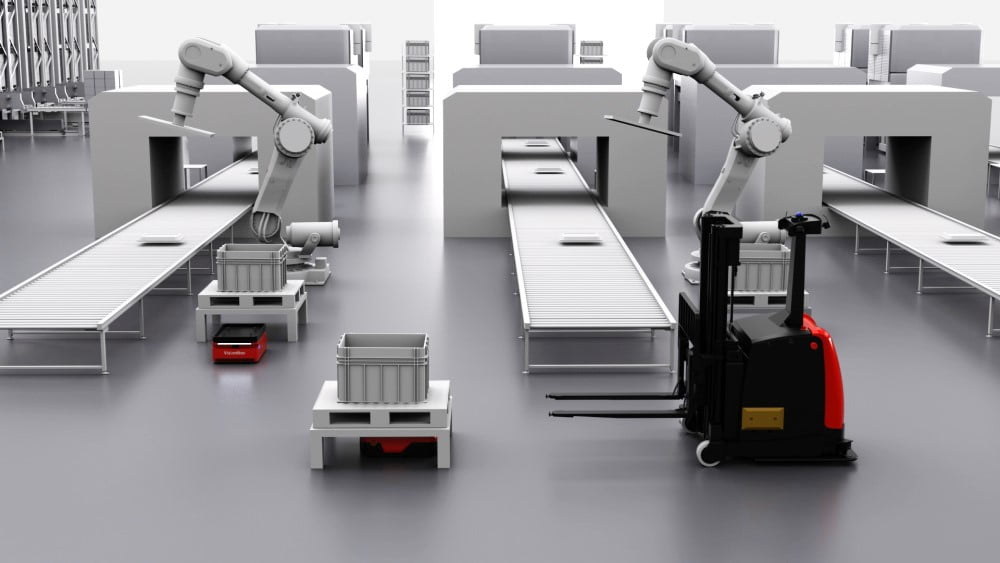

In a recent case study, VisionNav delivered a solution comprised of AMRs, a VNP 15 counterbalanced stacker, and the RCS(Robot Central System) 2.0. This integrated system was seamlessly integrated with robotic arms, enabling centralized management. The solution helps our clients increase intralogistics efficiency and develop their business output.

Inbound of The warehous

Inbound x VNP 15

Outbound of The warehous

Inbound x AMR

VisionNav is committed to further investigating diverse industry scenarios, persistently enhancing its comprehensive intralogistics automation solutions. This endeavor entails seamless coordination and efficient operations scheduling across diverse robotic systems, propelling intelligent logistics evolution within manufacturing and warehouse sectors.

About VisionNav

VisionNav® Robotics is a global supplier of autonomous industrial vehicles and intralogistics automation solutions. Based on Machine Learning, Environmental Perception, Deep Machine Learning, and Servo Control technology, VisionNav has developed nine product series for full-stack scenarios to automate industry logistics. VisionNav has served more than 30 countries and deployed 350+ projects around the globe, and partners with 50+ Fortune 500 companies, covering auto manufacturing, tire, food, petrochemical, e-commerce, 3PL, pharmaceutical, and other industries.

Media Contact

Iris Chen

xchen@visionnav.com