The surge in economic and population growth continues to drive an increase in fertilizer consumption worldwide. Over the next few years, demand for fertilizer is anticipated to remain steady in mature markets like Europe and North America, while Latin America and Asia are poised to fuel global growth. Projections indicate that global fertilizer demand will reach 208 million metric tons of nutrients by 2026.

As an "All-Round" warrior in the VisionNav forklift fleet, the Model E Counterbalance Truck AGV is hailed as the champion forklift of the year, due to its outstanding performance and scene adaptability. VNE30 has officially launched its first project in the localized fertilizer industry. Our client is a leading enterprise in the fertilizer industry, and the on-site materials for the project are finished products of soft package compound fertilizer. VisionNav conducted a comprehensive evaluation of the previous workflow, introduced four VNE30 counterbalance AGVs with the (Robot Control System)RCS. The system is integrated with the control system of the disassembly machine and the conveyor line system, realizing processes such as finished product offline storage, two-layer soft package stacking, and replenishment of empty pallets.

Addressing Key Challenges

1\In order to increase warehouse storage efficiency, the VNE30 autonomous forklift is required to pick up finished products of soft package compound fertilizer and complete two-layer stacking. The main characteristic of soft package materials lies in the deformation caused by compression during stacking, resulting in varying heights for fully loaded pallets of materials.

2\The project utilizes L-shaped 6-hole pallet carriers, requiring a high level of precision for the autonomous forklift to navigate the limited space when entering the holes.

3\Maintaining specific spacing between fully loaded pallets during the transfer from the conveyor line to the ground storage area is crucial, with a requirement for front, rear, left, and right spacing of ≤200mm.

Sustainable Workflow

Product Roll-off: After the robotic arm completes stacking the compound fertilizer products, fully loaded pallets are conveyed to the end of the line, triggering a photoelectric sensor. The RCS system receives the signal, generates task instructions, dispatches the VNE30 to pick up the fully loaded pallet materials from the conveyor line, and transfers them to the ground storage area. For partially loaded pallet materials, the VNE30 autonomous forklift will be dispatched to other designated storage locations.

The VNE30 autonomous forklift possesses robust carrier recognition capabilities, allowing it to detect the dimensions of the 6 pillars on the L-shaped 6-hole pallet accurately. This enables precise entry and retrieval of pallets. When transporting fully loaded pallets to the ground storage area, it ensures that the spacing between fully loaded pallets and adjacent pallets is maintained at ≤200mm.

For partially loaded materials, the VNE30 will transfer them to other designated storage locations. This prevents severe incidents during stacking storage, as partially loaded pallets may be unable to stack properly due to height differences.

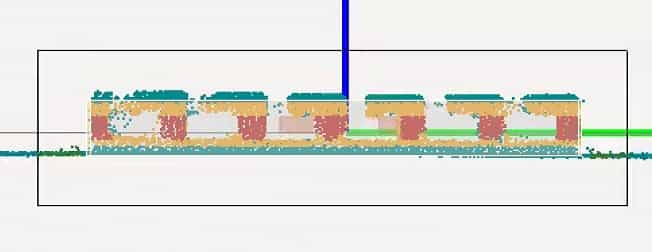

Soft Package Stacking: When the robotic arm stacks soft package materials, there are slight height variations for each pallet. The VNE30 counterbalance AGV initiates unloading perception, adjusting its own position by detecting the pose and height of the goods. It searches for an appropriate unloading height to accomplish two-layer stacking of soft package materials.

Empty Pallet Replenishment: Upon detecting insufficient empty pallets, the disassembly machine control system requests the RCS system. The VNE30 is then dispatched to pick up empty pallets from the designated area and transport them to the online empty pallet area.

Throughout the entire process, the VNE30 autonomous forklift interfaces with the disassembly machine. When the autonomous forklift reaches the disassembly machine, the disassembly machine stops its operation until the autonomous forklift safely places the empty pallet onto the disassembly machine, exits the disassembly machine, and then the disassembly machine resumes its operation.

Logistics Better

Solid rubber tires provide strong ground adaptability: The project site features a complex terrain with numerous bumps, trenches, and artificial water puddles. The VNE30 autonomous forklift is equipped with solid rubber tires, offering robust adaptability. This allows for smooth operation on challenging surfaces while maintaining high operational efficiency.

Quick 3D positioning and mapping targets larger site area: The project site covers an area of nearly 15,000 square meters. The VNE30 autonomous forklift utilizes 3D laser radar positioning, completing on-site mapping in approximately 20 minutes. This eliminates the need for external markers such as QR codes or reflective panels, significantly reducing both the time and manpower costs required in the initial stages of the project.

Two-layer soft package stacking, enhancing storage space: Soft package stacking has always been a major challenge in stacking scenarios, especially in industries such as fertilizers. In order to maximize ground storage space, multi-layer stacking of materials is almost a necessary process. With its powerful sensing and scene adaptation capabilities, VNE30 Counterbalance AGV overcomes the challenges of soft package stacking. This automation process can be replicated and applied to similar industries, assisting customers in improving warehouse storage capacity.

Peripheral device integration, coordinating with conveyor line cycles: The VNE30 interfaces with external devices such as the conveyor line and disassembly machine through the RCS system. It synchronizes with the robotic arm stacking, the finished product roll-off cycle, and the pace of empty pallets going on the production line. This ensures that the VNE30 autonomous forklift meets the customer's on-site requirements for efficient transfer and storage of finished products.

Intelligent dispatching of vehicles, internal logistics automation: The VisionNav RCS 2.0 central control dispatch system interfaces with the customer's disassembly machine control system and conveyor line system. It intelligently dispatches all vehicles throughout the entire process without the need for manual intervention. This automation saves labor and time costs, reducing the risk of stacking errors.